This article is adapted from a talk given in November 1979 by Mr Donnachie to the Lambeth and Southwark Archaeological Society.

The Victorian age was the age of steam power, not only for steamships and railway engines, but for a multitude of smaller applications where nowadays we would find an electric motor or diesel. Pumps, cranes, presses and workshop machinery all relied on steam. For a period of perhaps 50 years, however, between the 1880s and 1940s, a rival source of power challenged steam in the commercial and industrial fields, and was seen by many people at the time as the most modern method of propulsion – hydraulics.

In 1871 the Steam Wharf and Warehouse Co was formed to exploit the possibilities of hydraulic power, which had already been well known and used by Victorian engineers such as Brunel. This company was the brainchild of Edward Ellington (1845-1914) who was director of the Hydraulic Engineering Co of Chester and who successfully launched other hydraulic power enterprises in Hull, Liverpool, Birmingham, Manchester, Glasgow, Melbourne, Sydney, Antwerp and Buenos Aires. His method was to install a system of pipes, running below the London streets to reach a large number of commercial premises. The pipes, made of cast iron and carefully jointed, conveyed water at a pressure of 800 pounds per square inch. They formed a network of mains, rather like a gas or electricity main, which could be tapped by consumers to drive machinery of almost any type. Each consumer had a meter, read periodically by the company, which recorded how much water had been used from the hydraulic supply. The pressure was maintained by a huge triple-expansion steam engine at a powerhouse in Wapping; coal for the boilers was brought up the Thames by barge.

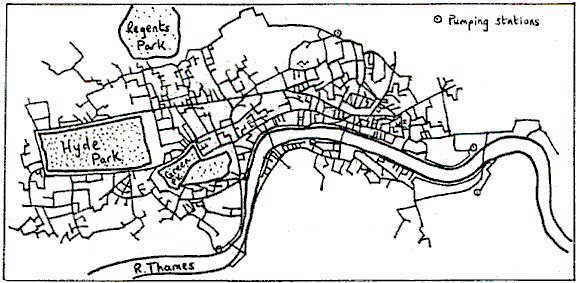

After some early vicissitudes, the company obtained its own Act of Parliament in 1883, and the sponsorship of the distinguished Victorian engineer, Sir John Allport. It then enjoyed a rapid growth of business, under the new name of the London Hydraulic Power Company. The hydraulic mains spread throughout the city, reaching Camden, Chelsea and Kensington. Most of the northern part of the Vauxhall Society’s area, around Waterloo, Lambeth and Kennington was served. The company built up its own construction and maintenance force, diversified and absorbed the Vauxhall Engineering Company. There were demands for hydraulic power to be provided in all major cities as a public utility.

The new system brought environmental changes – hundreds of workshops and offices previously using small, labour-intensive steam engines, (with all the attendant smoke and noise) changed over to a clean, quiet and reliable alternative. Drawing its water from the Thames, the company’s charges were always extremely reasonable: £2.50 per thousand gallons was a typical charge even well into the 20th century. In fact, for many applications, hydraulic power was for a long time cheaper than electricity.

The system had its curiosities too. Water in the mains was warmed to prevent freezing, which had the happy side effect of melting snow and ice on the pavements beneath which the mains were laid. Bursts in the system (fortunately rare) could produce a jet of water 100 feet high. Understandably, the company had the right to dig anywhere at any time in the London streets in order to put trouble right.

At the height of its fortunes, in 1930, the London Hydraulic Power Company supplied 8,000 machines with power through 186 miles of pipes. It consumed 33 million gallons of water per week, much of which ultimately returned to the river after use. Yet the competition from electricity eventually proved irresistible. The company’s final closure in 1977 probably resulted from a failure to adapt to changing conditions. For long, electric power in any form was barred from the company’s premises. Staff lived in awe of Ellington’s methods, and an air of comfortable self-satisfaction prevailed among the management. Wartime destruction of the city wrecked much of the hydraulic business and a belated conversion to electric control systems in the 1950s could not stem the gradual drift of customers towards oil and electric power.

The company seemed to lose its way when it should have been renewing its investment and promoting its advantages. It was the subject of a takeover in the 1960’s and its major assets of land, buildings and subsidiary firms, sold off. Gradually, the remaining users were advised of the termination of their supply, leading up to final abandonment of the system in 1977.

Since the above article was written much of the pipe network was subsequently bought up by Mercury Communications who used the pipes as a ready-made conduit for fibre optic cables used in their telecommunications business. The buildings at Wapping were restored during the mid-1990s and part has since been converted for use as a theatre and exhibition venue by the Women’s Playhouse Trust. The building is Grade II listed and some of the original machinery has been retained inside the Pumphouse.